Blade Steel: Why the Heat Treat Really Matters

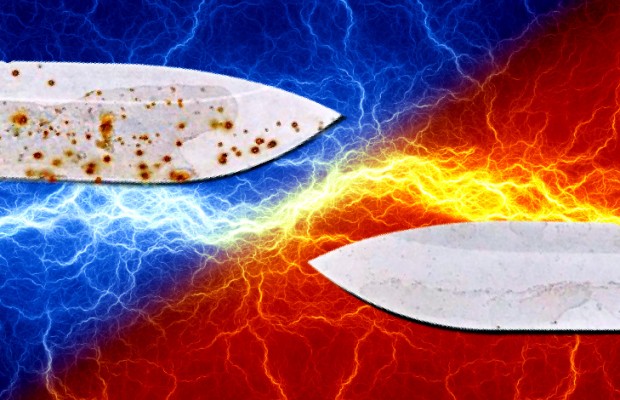

If you care how your blade cuts, the heat treat really matters. Heat treating is like baking dough into bread, but with steel: it turns raw, soft alloys into hard, tough blades capable of taking and holding an effective cutting edge. Heat treating is performed roughly halfway through the knife making process; before final grinding, finishing, and sharpening. To learn more about this under-appreciated yet crucial step, we reached out to the experts at Buck Knives and SURVIVE! Knives Founder Guy Seiferd.

> > Keep your folders awesome. Grab a Pack of 5 Microfiber Blade Sleeves for $8.99 < <

Heat treating is as old as metallurgy itself. Steel, at its most basic level, is a mixture of two elements: iron and carbon. Combined in the right proportion, they form an alloy that can go on to become a hardened, useful cutting tool. But simply adding a little carbon to iron isn’t enough – raw steel is still relatively soft, because the carbon molecules settle into comfortable places within the alloy’s so-called ‘crystalline structure’ where they don’t have much effect on its overall strength or hardness. By heating the raw steel to a ‘critical temperature,’ the crystal structure rearranges itself, moving the carbon molecules into places where they wouldn’t otherwise fit. Then, by rapidly cooling this transformed steel (blacksmiths call this step “quenching”), the new, stronger crystalline structure is frozen in place.

“Each Steel has its Own Heat Treat Recipe”

At its core, the heat treat is a simple process: heat your metal up, then cool it back down. But, the devil is in the details and there can be serious consequences when done improperly. “Each metal has a specific chemical composition, so changes in physical and structural properties take place at different, critical temperatures,” Justen Bock, the Product Development and Engineering Manager at Buck Knives explains. “Bad heat treat can result in a blade that never gets as sharp as it could be, suffers from poor edge retention, and/or possesses a lack of flexibility making it prone to tip breakage and chipping along the edge,” he says. In order to get consistent results, you have to follow a detailed, specific process depending on the alloy. “Each steel has its own heat treat recipe that changes the crystalline structure, which is an important factor to the mechanical properties of the metal,” says Bock.

“Buck is a Market Leader in Edge Retention”

Of the many steels Buck uses, the most popular is its 420HC. It’s not the most advanced or expensive steel but it is consistently praised for a performance boost owing to Paul Bos’ heat treat recipe. Bos, one of America’s foremost authorities on heat treating steel, has developed the ‘recipes’ used for many of Buck’s steels. “Buck is a market leader in edge retention thanks to our steel selections and heat treat process pioneered by Paul Bos,” says Bock. “[His] heat treating system has proven to be the best in the business.” Bos’ proprietary process is an industry secret, but it’s not exclusive to Buck Knives. Bos also heat treats custom and small-run production knives for a fee.

“The Heat Treat Really Matters”

The changes that occur during heat treating aren’t visible, but they can affect virtually every physical property of steel: its strength, hardness, corrosion resistance, toughness, and more. SURVIVE! Knives founder Guy Seiferd, collaborating with Peters’ Heat Treat, Nathan Carothers, and Dan Keffeler, found that by simply tweaking the heat treat, they could make their CPM-3V blades much more resistant to corrosion. The same steel that rusted when exposed to the elements would remain virtually rust-free after the new heat treat protocol. “A lot of it comes down to the quality of the heat treat,” says Seiferd. “All other things being equal, the heat treat really matters.”

0 comments