Knife Maker Explains Why Forging Stainless Steel Matters

In the world of hand-made knives there are many makers out there who would say you can’t – or shouldn’t – forge stainless steel. But bladesmith Sean McWilliams has been a leading advocate for forging stainless. He believes the controversial technique can be used to increase the performance of modern stainless steels like S35VN.

“Forging is shaping hot metal with a hammer,” McWilliams explains. “The blade is drawn to a point and tapered, followed by the tang. The bevels on the blade, point, and the blade itself are forged to their finished shape.” Most knives today are made using stock removal processes. Machines like water jets, surface grinders, or CNC machines cut a piece of material into the shape of a blade without the use of heat or a hammer.

Diehard collectors simply appreciate the concept of a forged blade. “There’s energy in them,” is how McWilliams describes it. But he says the reason knife users should be seeking forged steel is that it offers tangible performance benefits in the form of ‘edge packing.’

Metallurgically, edge packing has been known about for hundreds of years and continues to straddle the line between art and science. McWilliams has found references to it in old blacksmithing manuals, which describe it as a key process used to strengthen plowshares. “It happens at the level of crystallization and in the heat range between crystal structures,” McWilliams explains. By hammering the steel at the edge of the knife, microscopic changes occur to the steel, aligning its crystalline structure. “In forging’s transformational heat range, the crystals can be ‘jiggled’ into a tighter, more organized structure along the edge.”

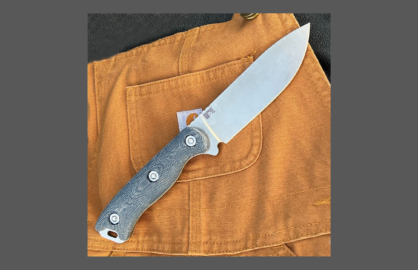

The result of this organization is enhanced edge retention, reducing the need for sharpening in the long-term. McWilliams says he has seen noticeable jumps in this category on various steels. He has worked with 440C, ATS-34, 154CM, S35VN, T440V and 420V among others, all showing noticeable performance results. McWilliams plans to follow up his years of experience with forged stainless with something more formal. He imagines a structured test using his Model 1 fixed blades and the well-known super steel S35VN. “That would be the logical next step.”

The performance benefits are real, but McWilliams is quick to point out that edge packing is not a miracle solution. “A packed edge is definitely a better edge in any steel, but it can’t make up for what a steel hasn’t got in it.” And he notes that while forging is theoretically possible on a production level, time-consuming edge packing isn’t. The chances of us seeing either process implemented on a production level are next to none, so they will likely remain relegated to custom work.

But there’s another hill that needs climbing too. A prevalent notion in modern bladesmithing is that you can’t forge stainless steels, and thus can’t pack the edges. McWilliams says this conception is flat out wrong. “To give up and publish that stainless can’t be forged has probably set the issue back thirty years. Forging and annealing instructions are printed on the MSDS sheets of all steels, including stainless,” he tells us. “I want to offer my customer the best performance in a knife. I could never go back to just grinding.”

Knife featured in image: Sean McWilliams Forge Model 1

0 comments