Lucas Burnley Weighs in on the Mid-Tech Question

Talk to any maker or collector and you’ll hear a different interpretation of what is or isn’t ‘mid-tech.’ Custom knife maker and designer Lucas Burnley has decided to abandon the term completely for his BRNLY Brand products. Burnley’s custom work is still marked by his full name on the blade. But when it comes to BRNLY models, the maker believes that the knife world and the term itself have changed so much that ‘mid-tech’ no longer accurately represents these products.

Originally, Ken Onion coined ‘mid-tech’ to describe a specific run of his Boa model. According to Onion himself, the parts were cut by an outside source, but he performed many of the other knife making processes in-house. “Mid-tech was supposed to let people know that it was made in part by the maker,” Burnley says. “But at this point, it’s gotten such widespread use that it includes products and brands outside of that original definition.”

Burnley feels part of the confusion stems from massive changes in the knife making landscape. Fifteen years ago, affordable CNC, laser cutters/engravers, and 3D printers were thin on the ground. Burnley, who owns a Haas CNC milling machine, says that this tech has come down in price so that small shops and even lone makers can afford them – and thanks to online resources, learn the skills necessary to run them. “Processes that were limited to larger-scale production are now more accessible to smaller craftsmen.”

Does the addition of one or two processes often associated with production automatically disqualify a knife from being called a custom? Some may feel that way, but Burnley thinks not. He never viewed CNC as a means of automation or increased production. Rather, it became a new method for developing his custom work. He treats it has another tool in his repertoire, a skill that he chose to learn himself.

However, Burnley notes that as custom makers are adding these processes to their work, production companies of all sizes are also leveraging custom techniques. Brands like Reate produce hand-ground, hand-rubbed blades. Outfits like Millit and Three Rivers Manufacturing implement multiple manual processes on batches of knives. RJ Martin himself chipped in for the recent TRM Neutron, sharpening each blade himself. ‘Mid-tech’ can now encompass all these situations and more.

So Burnley suggests approaching the problem from the opposite direction. “The big question isn’t ‘What is mid-tech?’ The big question is, ‘What is production?’” He says that production can mean mass production, like a run of 10,000 knives from one of the big brands. But today, it has expanded to also mean a batch of 100 knives from one of the smaller shops. That’s where he sees the BRNLY label falling. “It’s very subjective, but we’ve always strived for transparency,” Burnley explains. “The only area I’m able to accurately comment on is my own little niche. But for us, production is a more definable term. I no longer feel comfortable using the term ‘mid-tech.’”

He does however acknowledge the term’s importance, and the enormity of Ken Onion’s contribution in coining it. “Ken gave something that’s been 100% adopted by the industry.” And no matter what it comes to mean over the years, ‘mid-tech’ will always be part of the community’s lexicon. “The thing about terminology is that once it’s ingrained, it’s hard to remove it – no matter what aspects of the industry it grows to encompass.”

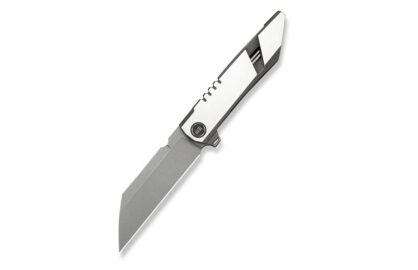

Knife featured in image: BRNLY Kihon

0 comments