WAZER Desktop Waterjet to Help Knife Makers Cut Through the Busy Work

The WAZER is a Kickstarter project that reimagines the industrial waterjet cutter as a practical, relatively small and lightweight piece of hardware for any home workshop. It has some significant limitations, but the opportunities it presents for simplified fabrication and rapid prototyping mean that aspiring knife makers should take notice.

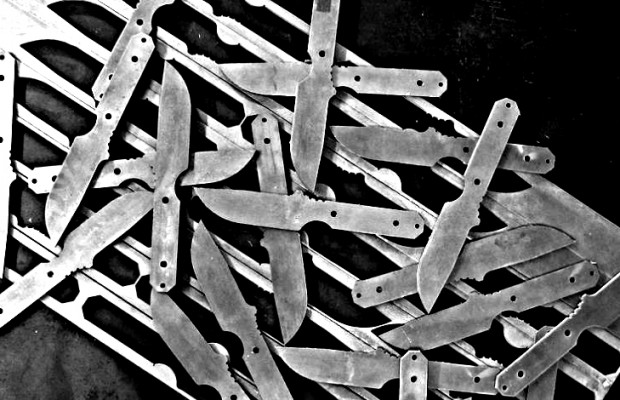

Waterjet is an efficient, precise method for cutting materials. In knife making, it’s used to blank out blades, handles scales, lock faces, and more. Until now, makers who couldn’t afford the five-figure-and-up cost of an industrial waterjet cutter had to do the cutting by hand (usually on a band saw), or source parts from waterjet cutting shops.

Dan Meana, a Mechanical Engineer formerly with Benchmade Knife Company and now part of the product development team at WAZER, says their hardware can help knife makers save their most critical resource – time. “With the WAZER you’re not sitting in front of a band saw all day,” Meana points out. “We like to think of the WAZER as the 21st century band saw.”

The WAZER Desktop Waterjet also makes rapid prototyping easier. Part designs can be tested and changed quickly without the wait times associated with sending parts back and forth from a waterjet shop. The WAZER is also a promising tool for making one-off knives or special projects. “Sometimes you want to make a knife without committing to 25, 30 of them,” Meana says

The WAZER is just 34”x25”x21”, a practical size for most workshops. When cutting, it uses 10-20% less water than an average showerhead. In contrast, most full-size industrial waterjet cutters require a lot of space, a lot of water, and a lot of maintenance. Because they shoot abrasive-filled water in a 40,000+ psi stream, waterjet cutters are maintenance-heavy machines. The pressure on the WAZER has been scaled way back. “We were able to alter the pressure output so that the WAZER isn’t aggressively destroying itself,” says Meana.

> > Keep your folders awesome. Grab a Pack of 5 Microfiber Blade Sleeves for $8.99 < <

This makes the WAZER a different animal than a full-size waterjet. The reduction in pressure means it takes the WAZER an hour and a half to cut what a standard waterjet can cut in less than ten minutes. Meana says that the WAZER isn’t meant to replace full-scale waterjet cutting. Instead, it offers some of the benefits of waterjet cutting on a smaller scale, and makes it much more affordable. “We wanted to give individuals access to the same tools that the industry has.”

0 comments